Choosing the right printing method for your business cards can make a significant difference in both your budget and the professional impression you create. When it comes to offset printing vs digital printing for business cards, understanding the key distinctions between these two popular methods is essential for making an informed decision that aligns with your business needs.

Whether you’re launching a startup or refreshing your existing brand materials, this comprehensive guide will help you navigate the choices and select the printing method that delivers the best results for your specific situation.

What Is Digital Printing and How Does It Work?

Digital printing represents a modern approach to producing business cards that works similarly to your office printer, but with professional-grade equipment and superior results. The process transfers your digital artwork directly to the printing press without requiring physical plates or extensive setup procedures.

This method uses either laser or inkjet technology to apply toner or liquid ink directly onto the cardstock. The beauty of digital printing lies in its simplicity and speed. Your design file goes straight from the computer to the press, eliminating many time-consuming preparatory steps that traditional methods require.

For businesses exploring digital printing solutions, this technology offers remarkable flexibility. You can print exactly the quantity you need, whether that’s 25 cards or 250, without worrying about minimum order requirements. The process also enables variable data printing, which means each card in your batch can feature different names, titles, or contact information without additional costs or production delays.

Understanding Offset Printing Technology

Offset printing, also known as offset lithography, is a traditional printing technique that has served as the industry standard for decades. This method involves transferring ink from a metal plate to a rubber blanket, and then onto your business card stock. The indirect transfer process is where the term “offset” originates.

The process begins with creating plates for each color in your design. These plates are mounted on cylinders within the printing press. As the press operates, ink is applied to the plates, transferred to rubber blankets, and finally pressed onto the paper. This multi-step approach creates exceptionally sharp, clean images with consistent color throughout the entire print run.

Offset printing excels at producing large quantities with superior color accuracy and consistency. The method uses Pantone Matching System (PMS) colors, ensuring your brand colors appear exactly as intended across all printed materials. This precision makes offset printing particularly valuable for businesses with strict brand guidelines.

Offset Printing vs Digital Printing for Business Cards: Core Differences

The fundamental differences between these two methods influence everything from cost to quality and turnaround time. Understanding how each technology operates helps you choose the right option for your business needs.

Digital Printing Technology:

- Operates on a straightforward principle where images are created through microscopic dots of toner or ink

- Works best with CMYK color models and can produce millions of color combinations

- Transfers digital files directly to the printing press without intermediate steps

- Uses either laser or inkjet technology for immediate image reproduction

Offset Printing Technology:

- Uses a chemical process where oil-based inks and water interact on the printing plate

- Requires a separate plate for each color in your design

- Layers inks sequentially to build the final image

- Delivers remarkably precise reproductions with superior color fidelity

Setup requirements differ dramatically between the methods, affecting both timeline and initial costs. Digital printing requires minimal preparation since files go directly from computer to press. This streamlined workflow eliminates many traditional printing steps, allowing production to begin almost immediately after file approval.

Offset printing demands more extensive preparation, including:

- Metal or polyester plate creation for each color

- Press calibration and adjustment

- Custom ink mixing to match exact color specifications

- Initial test runs to ensure quality standards

While these setup requirements add time to initial production, offset printing becomes increasingly efficient as quantities increase. The per-unit production time actually decreases with larger runs, making it highly cost-effective for bulk orders.

Cost Comparison: Which Method Fits Your Budget?

Digital printing uses a flat pricing model where per-unit costs remain fairly consistent whether you order 50 or 500 cards. The primary expenses involve equipment maintenance, toner, and labor. Without plate creation or extensive setup requirements, you avoid substantial upfront costs. This makes digital printing ideal for businesses testing new designs, needing quick card replenishment, or ordering smaller quantities.

Offset printing operates on a completely different economic model. The initial setup costs, including plate creation and press preparation, represent significant upfront expenses that make small runs expensive.

However, once the press is running, the per-unit cost drops dramatically with volume. A run of 1,000 cards might cost only slightly more than 500 cards because setup expenses remain constant while production costs decrease as quantity increases.

Cost-effectiveness by quantity:

- Under 500 cards: Digital printing typically offers better value

- 500-1,000 cards: Both methods become competitive, depending on specific requirements

- Above 1,000 cards: Offset printing generally provides superior cost efficiency

Keep in mind that these thresholds can vary based on your specific design complexity and paper choices.

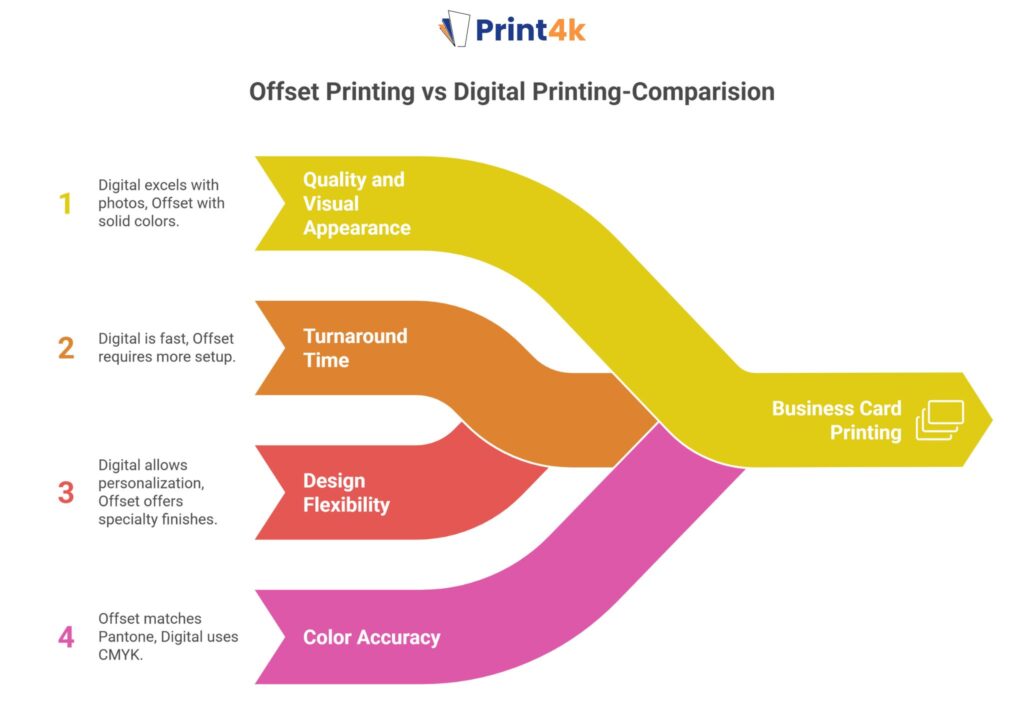

Quality and Visual Appearance

Visual quality differences between these printing methods can range from subtle to significant depending on your design. Digital printing produces excellent results for most business card designs, particularly those featuring photographs, gradients, or complex color blends. Modern digital presses achieve resolution up to 2400 dpi, creating sharp text and crisp images.

However, digital printing has limitations with solid color coverage and certain specialty finishes. Large areas of solid color may show slight variations from the toner application. The process also struggles with metallic inks and specialty effects that offset printing handles effortlessly.

Offset printing delivers superior color consistency across the entire print run. The ink sits on top of the paper rather than being absorbed into it, creating richer, more vibrant colors with better opacity. This characteristic proves particularly valuable for designs featuring dark backgrounds or colors requiring exact matching to existing branded materials.

For businesses seeking UV printing services, it’s worth noting that UV-cured digital printing offers enhanced durability and a distinctive glossy finish that adds dimension to specific design elements, though it operates using digital technology rather than traditional offset methods.

Turnaround Time Considerations

When deadlines matter, understanding production timelines becomes critical. Digital printing excels at rapid turnaround, with many print shops offering same day business card printing for orders placed early in the morning. The minimal setup requirements mean your cards can progress from approved artwork to finished product in hours rather than days.

This speed advantage makes digital printing invaluable for last-minute events, unexpected networking opportunities, or situations requiring immediate card replacement. The ability to print on demand also eliminates the need to maintain large inventories that might become obsolete if contact information changes.

Offset printing requires significantly more time due to preparation and setup. Creating plates, mixing inks to exact specifications, and calibrating the press all consume time before production begins. Most offset printing projects require at least 5 to 7 business days from approval to delivery.

However, once an offset press is running, it produces cards remarkably quickly. The actual printing time for 1,000 cards might be only marginally longer than for 500 cards since most time investment occurs during setup.

Design Flexibility and Customization

Digital printing offers unparalleled flexibility for personalization and variation. Variable data printing allows each card in a batch to feature different information, making it simple to create cards for multiple team members in a single print run without additional costs.

This capability proves especially valuable for businesses with sales teams or multiple locations requiring cards for numerous employees. You can maintain consistent branding while customizing individual details, all within the same production run.

Digital printing also facilitates easy design testing. You can order small quantities of different designs, evaluate them in real-world situations, and refine your approach before committing to larger orders.

Offset printing, while less flexible for variations within a single run, offers superior options for specialty finishes and effects. Techniques like spot UV coating, metallic inks, and custom Pantone colors achieve results that digital printing cannot match. These premium finishes create memorable, tactile experiences that help your cards stand out.

Color Accuracy and Consistency

Color performance represents a critical distinction when evaluating printing methods. Digital printing uses the CMYK color model, mixing cyan, magenta, yellow, and black to create colors. While modern digital presses achieve impressive color ranges, they cannot perfectly reproduce all Pantone spot colors, particularly bright oranges, certain blues, and metallic shades.

For businesses without strict color requirements or those working primarily with photographic images, digital printing’s color capabilities are more than adequate. The technology handles gradients and photographic reproductions exceptionally well.

Offset printing’s ability to use Pantone spot colors ensures precise color matching across different print runs and different types of printed materials. If your business cards must match your brochures and letterhead exactly, offset printing provides the consistency necessary to maintain brand integrity.

Color consistency within a single print run also differs between methods. Digital printing can show slight variations from the first card to the last, particularly in solid color areas. Offset printing delivers virtually identical color across the entire run once properly calibrated.

Paper and Material Options

The substrate you choose for your business cards significantly affects the final impression. Digital printing works well with most standard cardstocks ranging from 80 lb to 130 lb cover weight. Coated and uncoated stocks both produce good results, though heavily textured papers may present challenges.

Offset printing accommodates virtually any paper type and weight. From thin text weights to extra-thick 32-point cardstock, offset presses handle diverse materials with ease. This versatility enables creative choices like ultra-thick cards that communicate solidity and permanence.

The ability to print on unusual materials also distinguishes offset printing. Plastic cards, metallic substrates, and other non-paper materials often require the pressure and ink characteristics that only offset printing provides.

For businesses in specific markets looking for business card printing in Mineola or printable business cards in Valley Stream, local print shops can provide guidance on material options compatible with their specific equipment, ensuring you select the optimal combination of printing method and substrate.

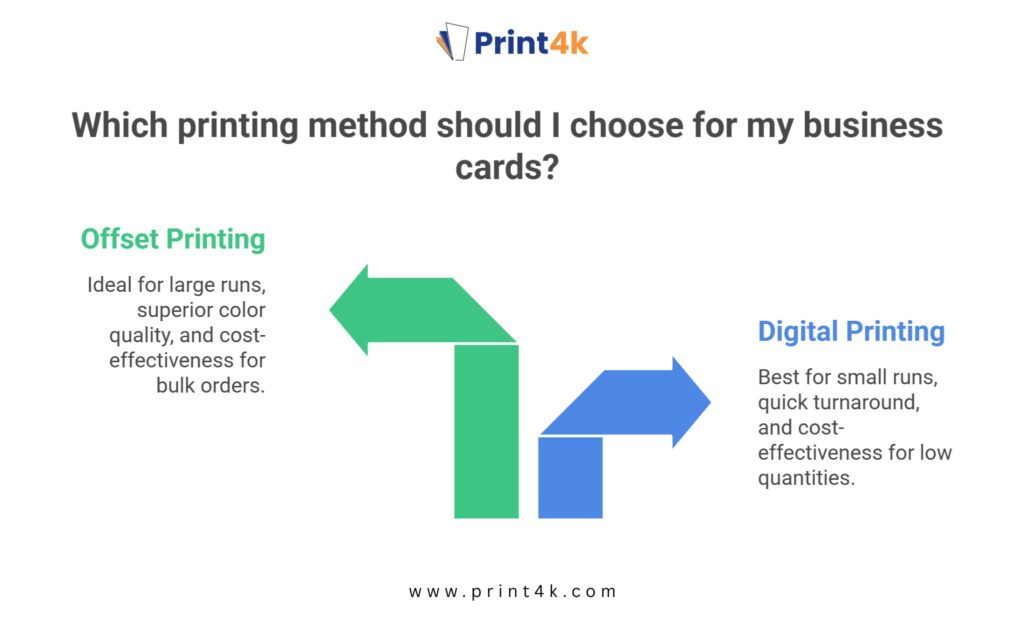

Making the Right Choice for Your Business

Selecting between these printing methods requires honest assessment of your specific requirements. Start by considering your quantity needs. If you regularly need small batches of cards, perhaps for new employees or updated information, digital printing offers the flexibility and cost-effectiveness you need.

If you have a stable team and can confidently order 1,000 or more cards at once, offset printing’s superior per-unit economics and quality advantages make it the smarter investment.

Timeline considerations also matter significantly. For urgent needs requiring quick turnarounds, digital printing’s speed is invaluable. For planned orders where you can accommodate a longer production schedule, offset printing’s quality benefits may outweigh the additional time required.

Your design complexity and color requirements should also influence the decision. Simple designs with standard colors work perfectly well with digital printing. Complex designs with specific Pantone colors or specialty finishes benefit from offset printing’s capabilities.

Conclusion

Understanding the key differences in offset printing vs digital printing for business cards empowers you to make informed decisions that align with your business goals, budget, and timeline. Digital printing offers speed, flexibility, and cost-effectiveness for smaller quantities, while offset printing delivers superior quality, color consistency, and value for larger runs.

Consider your specific needs, including quantity requirements, turnaround expectations, color accuracy demands, and budget constraints. Many successful businesses use both methods strategically, choosing digital printing for immediate needs and smaller batches while relying on offset printing for larger orders requiring premium quality.

By carefully evaluating these factors and consulting with experienced printing professionals, you can select the method that best represents your brand and creates the lasting impression you desire with every business card you distribute.